Great printing is our passion

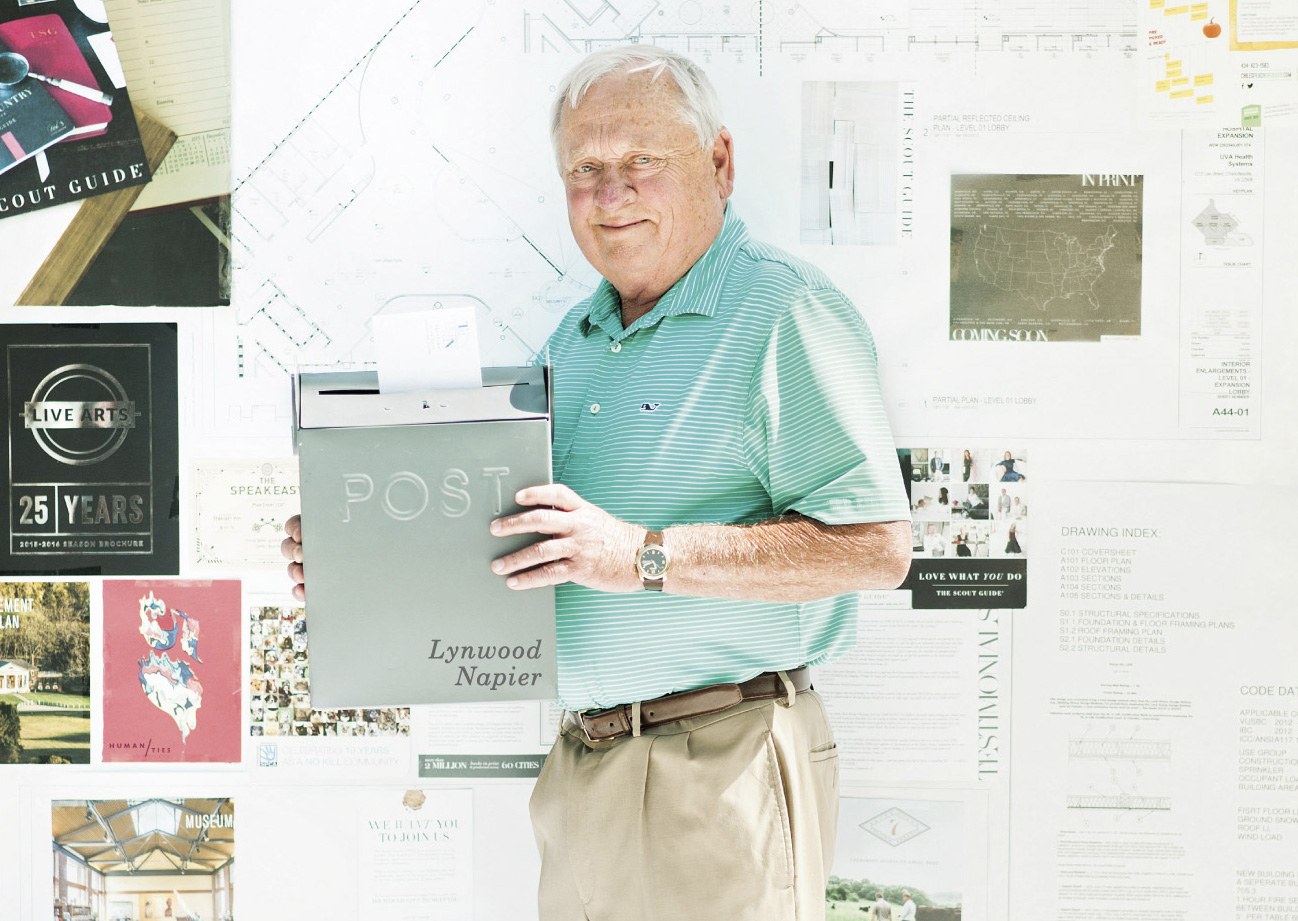

We’re good at it and we constantly strive to get even better. T&N Printing opened its doors in 1982 under the ownership of Lynwood Napier, and we quickly established ourselves as Charlottesville’s go-to printer. After decades of providing exceptional printing, we have become particularly known for our outstanding customer service and our promise of guaranteed satisfaction.

We cover the entire range of printing and duplication services, including full-color offset printing, state-of-the-art digital printing, and a full suite of bindery services. We also offer architectural blackline reproduction including sophisticated construction document management.

T&N’s crew of professionals are dedicated to making your printing process run as smoothly as possible. From the owner and managers, to the press and delivery personnel, we are all working every day to bring the best possible printing to our customers.

High-Quality Offset Printing

Still the pinnacle of quality in the printing world, offset printing will make your project stand out from the crowd.

Economical Digital Printing

Inexpensive, fast, and you print exactly as many as you need. Digital printing offers you a whole world of options.

Architectural Blacklines

The “blueprints” of the twenty-first century. Quick to produce, hi-res, durable, and environmentally-friendly.

Bindery Services

Printing isn’t the end of the story. We have all the bindery options you might need to help your project shine.

We also have other services available such as scanning, design, or promotional products. MORE

Your Hometown Printer:

Local, Friendly, and Community-Minded

Charlottesville is our home and we love being a part of this great community. We’ve been here for well over thirty years, providing top-quality printing and related services to all our customers across Central Virginia.

With decades of success built on close relationships and a history of great service, we’ve earned our reputation as one of the region’s favorite printers.

Key Personnel

Lynwood “Root” Napier

Owner

Phyllis Templeton

General Manager

Tamara Bickers

Customer Service and Office Assistant

Josh Shumaker

Blackline and Digital Department Manager

Environmentally Conscious

At T&N we take our responsibility to the environment seriously.